Thermoforming

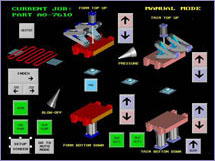

Our 14 state-of the-art inline thermoforming machines feature advanced automation designed to ensure ease of setup and operation. A fully computerized control system constantly enhances product quality and consistency, while reducing cycle times.

All of our high volume thermoformers are equipped with 2-axis robots, contributing to increased operating efficiencies. Very rigid frames and highly accurate positioning functions allow us to manage thermoforming applications requiring higher degrees of difficulty.

The inline finish cut process has been significantly improved by implementing our recently patented knife-like cutting die. With this new technology we have extended the life of our cutting dies by approximately ten times, and realized reductions in tooling related downtime, job setup time and cycle time.

The number of thermoforming lines continues to grow to accommodate ongoing expansion of the thin gauge business.

|

|

|

|